What is RFID technology and how does it work?

RFID stands for Radio-Frequency Identification - a

wireless

technology that uses radio waves to

automatically identify and track tagged objects (for example life vests). Each RFID

tag

contains a tiny

chip and antenna that stores data (serial number, expiration date, etc.). When it

comes

near an RFID

reader, the reader’s radio signal powers the tag and the tag sends its information

back

to the reader

without any physical contact. This allows for quick, automatic identification of

items

from a distance.

How is RFID used in the aviation industry?

Airlines use RFID in many ways to boost efficiency and

safety. For example, RFID tags on safety

equipment (like life vests or oxygen masks) are tagged so maintenance crews can

easily

monitor stock

levels, check expiration dates, and ensure everything is in place and up-to-date.

RFID

is also used for

security (badges controlling access to restricted areas) and even speeding up

boarding

with RFIDenabled boarding passes, improving the overall passenger experience.

How does RFID differ from barcode scanning?

RFID does not require direct line-of-sight to the item,

whereas barcode scanners must “see” each

barcode one by one. An RFID reader can scan dozens of tags at once, even if they’re

hidden or

embedded in equipment, making it much faster for tasks like life vest checks. RFID

tags

can also hold

more data and are often more durable (no printed label to wear out), while barcodes

are

simple visuals

that can be damaged or dirty. In short, RFID enables bulk, remote scanning, whereas

barcodes require

manual, close-up scanning of each item.

Does RFID require line of sight to work?

No. RFID tags can be read without line of sight - the

reader

uses radio waves that penetrate materials

like plastic or fabric. This means a crew member can walk through the cabin with a

scanner and detect

tags under seats or inside compartments without having to visually find each item.

This

is a big

advantage over technologies like barcodes, which would need a direct view of each

label.

How accurate is RFID scanning compared to visual

inspection?

RFID scanning is extremely accurate and far less prone to

human error than a visual check. Manual

inspections can miss items or lead to recording mistakes, but RFID automates the

process

and ensures

every tagged item is accounted for. In practice, RFID systems will alert staff if

any

required equipment is

missing or expired, providing near 100% verification of safety gear. By removing the

guesswork and

fatigue that come with visual checks, RFID makes inspections more reliable.

Why is RFID better than manual safety equipment checks?

RFID makes safety inspections much faster and more

reliable

than manual checks. Airlines have reported

cutting inspection times by as much as 95% by using RFID - a task that once took

over an

hour can be

done in just minutes. Because the scanner instantly reads all equipment tags,

nothing

gets overlooked

and human error is greatly reduced. The process also automatically logs the results,

so

there’s less

paperwork and more confidence that every life vest has been properly checked.

What types of safety equipment can be tracked with RFID?

Virtually any onboard safety item can be RFID-tagged and

tracked. Common examples include life vests,

life rafts, fire extinguishers, and oxygen tanks/bottles. Airlines also use RFID for

equipment like

emergency medical kits or defibrillators to ensure they are present and serviceable.

In

short, all crucial

emergency and safety equipment - from under-seat flotation devices to portable

oxygen

units - can

carry RFID tags so their status is monitored at all times. * Note that at this time

CabinTrack can only be

used to track life vests - in the future we are planing to expand the list of

emergency

equipment that can

be tracked.

How durable are RFID tags in an aircraft environment?

RFID tags used on aircraft are built to be very durable

and

meet strict aviation standards. Engineers

design these tags to withstand extreme temperatures, pressure changes at altitude,

vibration, and the

general wear-and-tear of cabin service. The tags are often sealed or reinforced so

they

remain readable

for many years. In the demanding environment of flight, specialized RFID tags ensure

reliability without

interfering with aircraft systems.

What maintenance do RFID tags require?

Typically, RFID tags require little to no maintenance.

Most

tags used for cabin equipment are passive -

they have no battery - so there’s nothing to replace. Once a tag is attached to an

item,

it can last for the

life of the equipment, only needing attention if it becomes damaged or detached. In

practice,

maintenance staff may occasionally verify that tags are still securely in place and

readable, but the tags

themselves don’t need regular servicing or power.

Can RFID technology be used beyond safety equipment checks?

Yes. RFID is a versatile technology that extends far

beyond

safety gear inspections. Airlines use RFID to

track many other assets - for example, tool kits and spare parts can be tagged so

maintenance crews can

quickly locate and manage them. It’s also used for inventory like catering supplies

or

cleaning

equipment, ensuring those items are where they should be. RFID technology has proved

its

effectiveness in aviation industry for years.

Can CabinTrack work offline?

Yes. CabinTrack is designed to work even when you don’t

have

an internet connection in the aircraft.

The handheld scanner can perform RFID scans offline, storing inspection data locally

during the flight or

while at a remote location. Once a connection is available, the system securely

syncs

the data to the

central CabinTrack platform. This means safety checks can be carried out anywhere,

anytime. * Note

that some specific scan types using CabinTrack requires Internet connection.

Can CabinTrack integrate with airline maintenance software?

CabinTrack can share data with your existing maintenance

and

record-keeping systems so that

everything stays in sync. In practice, this means you don’t need to manually

re-enter

data; CabinTrack

can automatically update your central maintenance system (such as an MRO or

compliance

database)

with the latest inspection info. * Requires consultation.

How quickly can RFID-based inspections be implemented?

RFID inspections can be up and running quickly. Tagging

the

cabin equipment is straightforward and can

be done during routine maintenance or overnight stops without taking aircraft out of

service. Most of

the life vests already have RFID tags on them, fitted by the manufacturer, other

need

separate tagging.

Some airlines fitted their first RFID-enabled aircraft in just a few months and then

rolled the system out

fleet-wide within the year. Once the equipment has RFID tags and the CabinTrack

system

is set up,

crews can begin using it almost immediately - the switch from manual checks to RFID

scanning is swift

and causes minimal disruption.

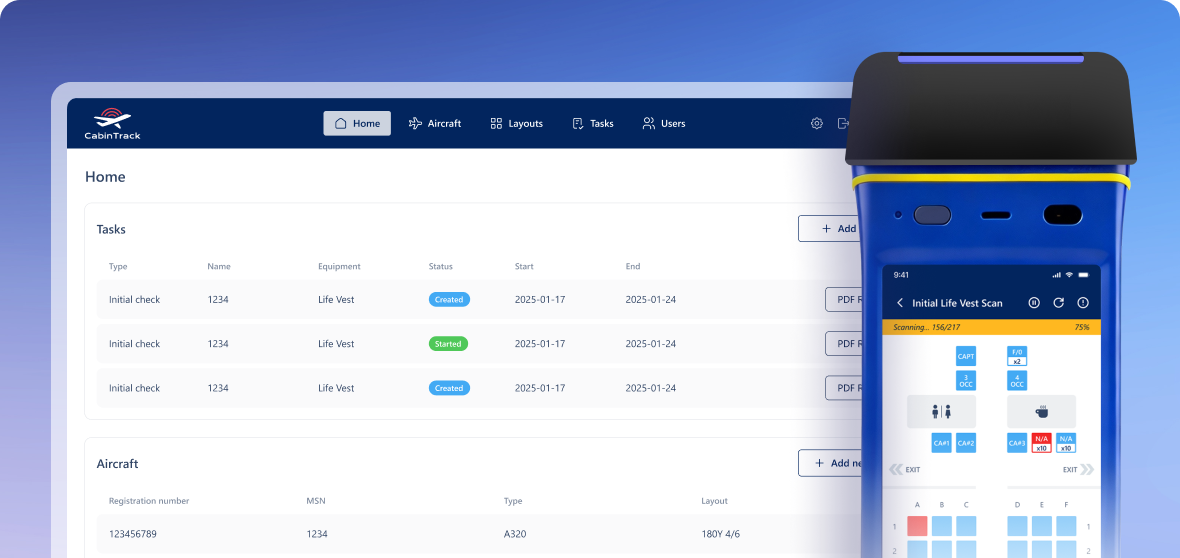

What hardware is needed for RFID scanning?

The essential hardware includes RFID tags on the items

and an

RFID reader device for scanning.

CabinTrack uses small, passive RFID tags attached to each piece of safety equipment.

A

handheld RFID

scanner is then used to sweep over the cabin and detect those tags. Other than the

tags

and reader, the

rest is software - the CabinTrack app - which guides the user during inspections.

The

hardware is

lightweight and portable, making it easy for crew or engineers to carry out checks

anywhere on the

plane.

What training is needed to use CabinTrack?

Very minimal training is needed. CabinTrack is built to

be

user-friendly, with an intuitive app interface

and simple scanning process. Most crew or maintenance staff can learn to use the

handheld RFID

scanner and CabinTrack software in a short session - essentially, if you can use a

smartphone or a

barcode scanner, you can use CabinTrack. We also provide supporting resources, but

in

practice the

system is straightforward enough that teams can get comfortable with it quickly.

How secure is RFID data in aviation?

RFID data can be made very secure. The CabinTrack system

and

RFID tags do not broadcast sensitive

information openly - typically, a tag might only contain an ID number, and all the

detailed data is stored

in a secure database. The communication between RFID readers are access-controlled,

so

that only

authorized devices and personnel can read or update the data. In short, the RFID

solution uses various

security measures to protect the information, ensuring that safety equipment records

are

safe from

tampering or unauthorized access.

How does RFID help with regulatory compliance?

RFID creates a reliable digital audit trail for safety

checks, which makes regulatory compliance much

easier. Every inspection and item status is logged automatically, so airlines can

easily

prove that all

required equipment has been checked and is within its expiration date. The system

flags

any missing or

expired items instantly, helping maintenance crews fix issues before a flight

departs.

By reducing the

chance of human error and missed inspections, RFID greatly lowers the risk of

non-compliance with

safety regulations. Overall, it gives regulators and airlines confidence that

nothing

has been overlooked,

and it simplifies the paperwork needed to demonstrate compliance.

What’s the return on investment for RFID inspections?

The return on investment for RFID-based inspections is

typically very strong. By saving countless labor

hours (for example, turning hours of manual work into minutes of scanning) and

avoiding

flight delays or

cancellations due to overlooked equipment, the system pays for itself quickly.

Airlines

see financial

benefits from reduced maintenance time, fewer errors (which means less rework or

fines),

and better

aircraft utilization. In many cases, RFID solutions like CabinTrack deliver a rapid

ROI

because they

streamline operations and prevent costly compliance issues, all while improving

safety

assurance.

How does RFID contribute to sustainability in aviation?

RFID can help airlines operate more sustainably in a few

ways. First, it enables more efficient use of

safety equipment - by tracking expiration dates and usage, airlines can use items to

their full life and

reduce unnecessary waste (for example, not discarding life vests too early or

carrying

extra equipment

“just in case”). Second, RFID inspections are largely digital, which cuts down on

paper

checklists and

manuals, contributing to a paperless cabin and less waste. Additionally, smoother

and

faster inspections

can indirectly support sustainability by reducing engine idling time on the ground

(since delays are less

likely) and optimizing maintenance schedules. All these factors mean RFID solutions

like

CabinTrack not

only save time and money but also support greener operations through waste reduction

and

improved

efficiency.